Get High-Quality Orlando Car Care Ceramic Coatings for Maximum Protection

Get High-Quality Orlando Car Care Ceramic Coatings for Maximum Protection

Blog Article

Experience Superior Protection With Ceramic Coatings: a Thorough Review

Ceramic finishings have actually emerged as an advanced remedy for those looking for improved defense for auto and commercial surfaces. As we discover the multifaceted benefits, application techniques, and exactly how they stack up versus conventional options, it comes to be obvious that the financial investment in ceramic finishes can redefine your strategy to surface area defense.

What Are Ceramic Coatings?

Ceramic layers are innovative protective layers used to surface areas, primarily in vehicle and industrial applications, to improve durability and resistance to environmental factors. Made up of silicon dioxide (SiO2) derived from natural materials, these coatings form a strong, hydrophobic layer that bonds chemically with the substratum, developing a resilient shield against different aggressors such as UV rays, chemicals, and physical abrasions.

The application process usually includes detailed cleaning and prep work of the surface area, adhered to by the precise application of the ceramic finish. When healed, the coating hardens into a resilient layer that can dramatically extend the lifespan of the surface area it shields. Unlike typical waxes or sealants, ceramic finishings provide a resilient service that requires minimal maintenance.

These layers are not restricted to auto finishes; they are also used in marine, aerospace, and industrial setups, where they give significant benefits in terms of efficiency and long life. Their flexibility and performance in protecting surface areas against wear and tear make ceramic coatings a significantly popular option for both professionals and lovers seeking to keep the stability and appearance of valuable assets.

Advantages of Ceramic Coatings

Furthermore, ceramic coverings show excellent hydrophobic residential properties, permitting water and various other liquids to bead up and roll off surfaces - Orlando Car Care Ceramic Coatings. This self-cleaning result considerably decreases the time and effort needed for maintenance, as dust and crud are much less most likely to stick. Furthermore, ceramic finishings are immune to engraving and damaging, which further maintains the integrity of the underlying surface

An additional vital advantage is the thermal resistance provided by ceramic finishings, which can hold up against high temperatures without degrading. This top quality is especially helpful for vehicle applications, where engine components and exhaust systems undergo severe warmth.

Application Process Clarified

Attaining optimum outcomes with ceramic finishings requires a thorough application procedure that makes certain correct attachment and performance. The very first step includes thorough surface area preparation, which is vital for accomplishing a smooth, clean base. This commonly consists of cleaning the surface to eliminate dirt, oil, and contaminants, followed by claying to get rid of embedded bits. For automobile applications, repaint improvement might be required to address flaws, ensuring the surface is as flawless as possible.

As soon as the surface is prepared, it is crucial to use the ceramic finishing in a regulated setting, preferably in a garage or shaded area to prevent direct sunlight and dust. Utilizing a foam applicator or a microfiber towel, the coating must be applied equally in tiny sections, permitting optimum navigate here control during application. A curing time of roughly one to two hours is advised prior to revealing the surface area to wetness.

After the initial curing, numerous layers might be put on improve durability and gloss, with each layer requiring ample curing time. It is critical to examine the surface area for any kind of high spots or irregular application and to rub these areas as needed, ensuring a flawless finish that makes the most of the protective advantages of the covering.

Upkeep Tips for Durability

Appropriate maintenance is vital to taking full advantage of the durability of ceramic finishes, ensuring that the safety layer continues to perform efficiently over time. Routine cleaning is critical; utilize a pH-balanced, gentle soap and a microfiber wash glove to prevent scraping the surface area. If exposed to rough elements., it is suggested to clean the car every two weeks or more frequently.

After washing, completely dry the surface area with a clean microfiber towel to avoid water areas. Additionally, applying a ceramic upkeep spray every couple of months can renew the finish's hydrophobic residential or commercial properties, improving a fantastic read security versus pollutants.

Prevent making use of rough cleaning devices, waxes, or sealers that may degrade the ceramic layer. Rather, decide for non-abrasive items especially made for ceramic finishes.

Examine the covering occasionally for any kind of indications of wear or damage, and address these problems promptly to preserve optimum efficiency.

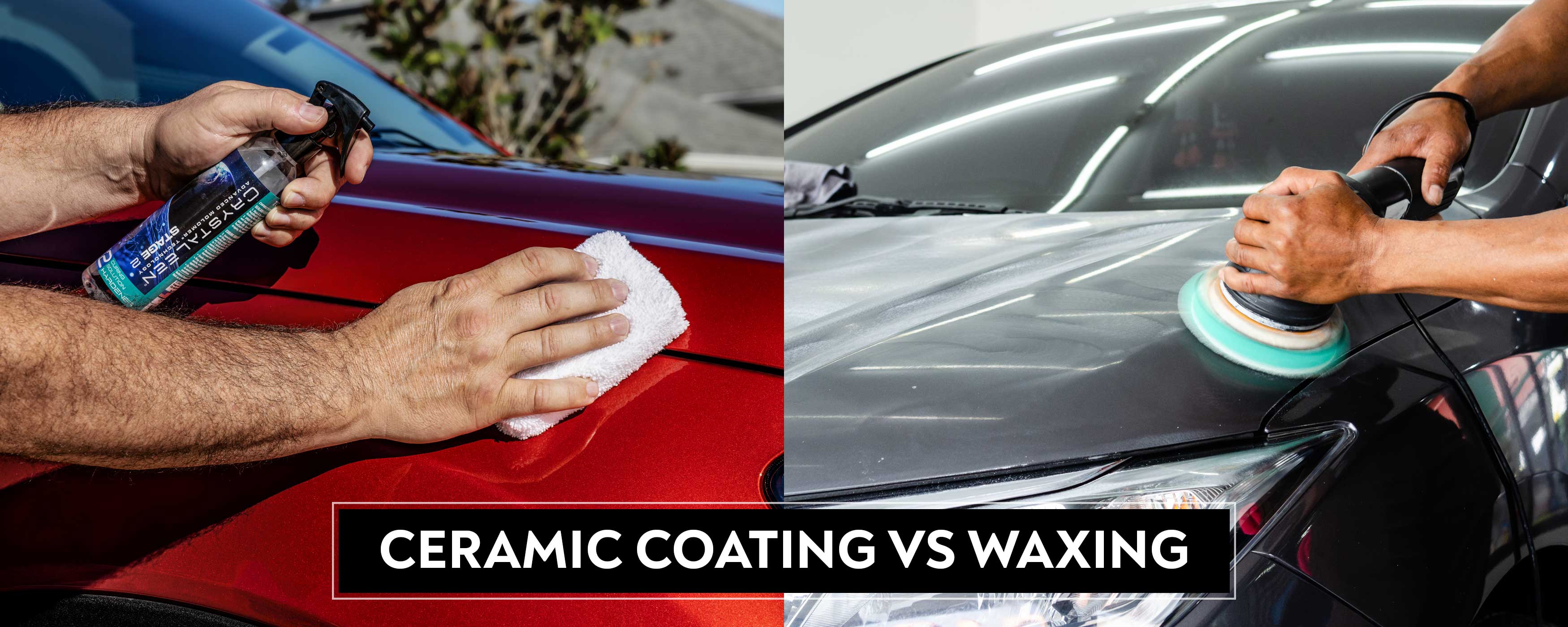

Comparing Ceramic Coatings to Alternatives

Preserving ceramic coverings is simply one aspect to consider when examining safety alternatives for automobile surfaces. When contrasting ceramic finishings to options such as wax, sealants, and paint security films, several important variables emerge.

Paint defense movies (PPF) are an additional prominent choice, giving exceptional physical security against chips and scrapes. They can be extra costly and may call for expert installment, unlike ceramic coatings, which can commonly be used by a skilled Do it yourself lover. Additionally, ceramic layers enhance the lorry's gloss and depth, providing visual benefits that choices might not match.

Final Thought

In final thought, ceramic coverings stand for a significant improvement in surface area protection for vehicle and commercial applications. With marginal upkeep demands and lasting performance, ceramic coverings not only guard the integrity of surfaces however also improve their aesthetic charm.

Report this page